K Rations

Pulitzer Prize–winning American journalist and war correspondent Ernie Pyle obviously about to enjoy a heaping spoonful of delicious ration Mystery Meat...

Outer Carton

First of all, it must be explained that the Quartermaster Corps makes a difference between 'packaging' and 'packing'.

It is called 'packaging' to pack similar products of the actual food together in a cardboard package, a paper wrapping or wrapped in cellophane.

Since the parts are bundled together, they are regarded as a 'package'.

It is called 'packing' to bring many different packages together in a single container.

This implies that the breakfast, dinner or supper units, as individual packages, were then packed together in the appropriate shipping crates. It's not at all complicated, huh?

From a May 1943 circular: The following distinction was made between packaging and packing. 'Packaging' involves the product itself and is often designed along with the product and is typically carried out at the point of source or manufacture. 'Packing' can be done at the point of origin or output, or in factories, or in the field, as in the case of organizational equipment.

The Quartermaster Corps hired outside firms to serve as a prime contractors. Such companies had prior expertise in the handling and packaging of foodstuffs, had sufficient space and manpower, and special processing equipment (such as waterproofing and package closing) for the inner and outer cartons.

The contents of the K Rations were ordered by the prime contractor from the authorized subcontractors which packaged them together in separate units. They were packed for shipping when the units were ready, twelve full rations in a case.

See above: Apparently, Lamont, Corliss & Company didn't pack the ration themselves.

Known prime contractors are:

- Lamont, Corliss & Company

- The Hills Brothers Company

- Beech-Nut Packing Company

- Wm Wrigley Jr. Company

- Patten Food Products

- H. J. Heinz Company

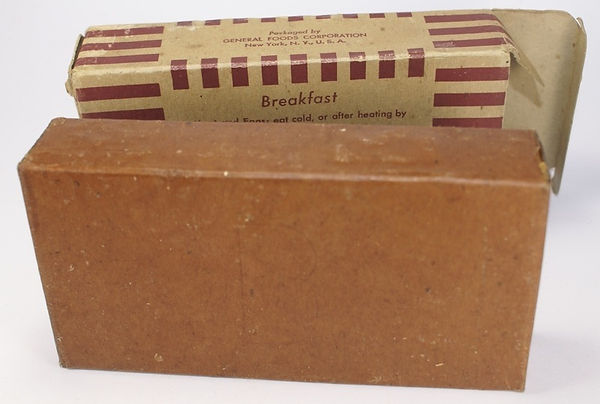

- General Foods Corporation

- Kellogg Company

- American Chicle Company

- Hiram Walker & Sons Incorporated

- Campbell Soup Company

- Phillips Packing Company

- The Cracker Jack Company

- Doughboy Mills, Incorporated

- Chas. A. Brewer and Sons

During the entire war, some firms served as prime contractors, others only early or later in the war, or only for one manufacturing run.

The K Ration elements were sealed in a carton. In order to weather- and gas-proof the wrapping, this carton was impregnated with a synthetic wax paste. The individual waxed cartons were put inside a tight-fitting outer carton to keep the waxed boxes from sticking together when enclosed in a box or crate.

A 1942 Signal Corps image displaying the latest K Rations wrapped in single wax-coated cartons. These can stay together in hot climates.

"U.S. ARMY FIELD RATION K BREAKFAST UNIT, DINNER UNIT, and SUPPER UNIT". The printing is on one or both sides of the outer carton primary sheet.

In order to mark the unit type when the rations have been loaded in a shipping box, a letter 'B', 'D' or 'S' was usually written on one or both ends.

In Normandy, a telephone operator stacked three units of K Rations (circled in red) on top of his switchboard.

I split them into four distinct categories because of specific differences in the nature of the labels on the outer cartons (with two sub-types). These are not official typifications, but for simple reference, they are what I use.

Type I: Only the "U.S. Army Field Ration K" nomenclature of unit type is written on the box. The nomenclature and the name and address of the packing firm were included in the early experimental procurement of K Rations, along with a list of contents printed on one main column.

With the content continually evolving due to its early development, it was difficult to balance any procurement with its list of contents.

It was determined that the carton would read only the name and address of the nomenclature and packaging business.

An exterior carton with its nomenclature and the unit written on both main panels and the name of the packager on both side panels. The "S" for Supper is available for all tuck-in end flaps.

The name and address of the company, which served as the prime contractor, which packed the food components into the carton, is printed on one or both side panels. The detail was sometimes printed on the main panel on the lower right corner.

Outer Breakfast carton from Patten Food Products - there were versions that were only printed on its front panel, so there are no side or end markings.

American casualties lying in a ditch near St. Marie du Mont, paratroopers killed on D-Day. Note the early type I K Ration next to the troopers' helmet.

Type II: Informational text is extended to the unit's front panel. On the back, components are identified. Experience from field testing found out that before finally opening a ration, the soldier had no notion of its contents or how to prepare them.

It was determined in February 1943 (after the introduction of a matchbook in the Dinner unit) that in addition to the name of the ration and unit, one key panel introduced the following suggestion:

"Open inner [cellophane] bag carefully, it may be used as a waterproof container for matches, cigarettes, etc." and for security, do not discard the empty can, paper or refuse where it can be seen from the air. If possible, cover with dirt, foliage, sand, etc."

A suggestion to include a document containing a list of contents and instructions for preparing was not approved, since the soldier would also have to open the carton in advance to read the list.

The directions for the Hills Brothers Packed Supper Unit:

The back panel was printed with a list of contents and preparation tips.

Only "Ham & Eggs" are listed on all exterior cartons of the breakfast units. Either the Ham & Eggs can or the Pork & Egg Yolk can may actually be found in the unit. The text also notes that Cheese may be substituted for Egg. This was done when neither egg product was available.

The Cheese brand may be any of the cheese varieties produced.

The Supper unit selection for the canned meat food may be any of the available meat varieties. Again, it may be replaced with cheese.

K Rations I have seen thus far included their respective items of egg, cheese or beef. The firms were evidently capable of manufacturing the requisite quantities, so it appears that cheese was only rarely used as a substitute.

The back of a Breakfast unit listing Ham & Eggs. Note that cheese may be furnished. General Food Corporation, early 1944. (photo K Ration Info)

List of contents in a box for the Dinner unit packaged by Patten Food Products (Mid 1943). This unit might contain either lemonade or orange juice powder. While four lumps of sugar are listed, this individual unit instead contained a package of 23 grams of granulated sugar. (Late 1943)

Nurses in England are receiving Type II K Rations and other PX supplies for their journey to Normandy in 1944.

Type IIIa: Change the nomenclature to "Ration, Type K" (1943, May/June)

In May/June 1943, the nomenclature in all of the U.S. Army rations had been changed to "Ration, Type K" followed by the Unit Type (Breakfast, Dinner or Supper). All the other facts remained the same as before, only the name of the ration was changed on the cardboard.

It should be noted here that I cannot pinpoint the exact date of the nomenclature change. There was an objection to the name "United States Army 5-in-1 Ration" for use on the 5-in-1 Ration in March of 1943 and that it should be in the conventional reverse military order: "Ration, 5-in-1".

The term "United States Army Ration: Five-in-One" is included in official requirements released on 1 May 1943. The nomenclature "Ration, Ten-in-One" was used one month later (7 June 1943) for the new 10-in-1 Ration.

Ration, Type K. Made by the Patten Food Products (the same company that packaged the 23 grams granulated sugar cartons). The lay-out of the label was left to the packing company, as long it carried the essential information approved by the QMC. (photo K Ration Info)

Type IIIb: Malaria warning is added on a side panel. (February 1944)

In the fall of 1943, a request came from the Office of the Surgeon General for a malaria prevention warning to be placed on the K Ration outer carton. At first this was objected to, reasoning that malaria prevention was part of training. It was feared that if an excessive number of warnings appeared on ration packaging, they could become so common that eventually nobody would bother to read them.

In February of 1944, however, it was decided that the warning "NOTICE: mosquito bites cause malaria. If you are in a malaria zone, keep your shirt on and your sleeves rolled down. Use mosquito repellent when out of doors between sunset and sunrise." was to be printed on one of the side panels.

Type IVa & IVb: The colored "morale" boxes are introduced. Components are the same as Type IIIb, but are mentioned in a more generic list. (May 1944)

Late 1943 a new school of thought occurred within the Army. Instead of providing the soldier with a ration that is packed unattractively and is therefore not very inviting, why not make it a little more attractive to the soldier by using an appealing design and color.

Four of several proposed multi-color designs.

Several multi-color designs were considered, but ultimately a one-color design for each meal was chosen. Each unit was printed with a different design in a color of low visibility. The use of different colors and designs facilitated not only distribution in the field, but also helped the packagers in the production plants to readily identify the units, thereby speeding up the production process and preventing mixing of units. It was determined that a color or a specific design was easier to recognize as opposed to reading every label.

It was even suggested that the inside of the outer carton could be printed with various board games, like checkers or dominoes. This idea was not acted upon, because it was felt that a frontline soldier would not have the time or inclination to play games in his foxhole. I guess the higher-ups didn't realize that 90% of time spent in the army is WAITING...

Printing plates for the new designs were prepared by the Lake Shore Electrotype Co. and provided through the Chicago office of the Quartermaster General to the carton manufacturers.

The Breakfast unit was printed with a striped design in brick red, the Dinner unit had a dark blue irregular "bubble" design, and the Supper unit was printed in a green design that featured straight lines, curves and stars.

Early 1944 the new designs were approved and went into production in May that same year. Thess versions of the K Ration boxes are generally referred to as "Morale" Boxes.

"Not only are the three meals readily identifiable, but the drab monotony of one-color printing is relieved. The designs are bold, masculine, and impersonal. The colors have low visibility and use a minimum amount of ink. Outstanding packaging designers contributed generously to this project, and the treatment is an import advancement in Army Packaging policy."

This idea of making a field ration 'attractive through design' turned out to be a failed experiment. The soldiers who ate the rations still judged, and generally condemned, the ration by its contents, no matter how joyful the packaging. This new approach to packaging was only tried with the K Ration (and the Air Crew Lunch, but this was not a field ration). While the idea was also suggested with the 10-in-1 Ration, this was not acted upon. (photo K Ration Info)

The USAAF Air Crew Lunch of a bright red and dark blue design.

Another subtle change with the ration's outer carton is the gradual lowering of the quality of cardboard used. While in 1942 only the highest quality of lined kraft paperboard was allowed, the quality deteriorated to a cheaper chip kraft cardboard, to an even slightly thinner grey recycled cardboard in 1945.

The period a particular K Ration unit was produced can roughly be determined by its outer box design. Slight differences in design or content list varied with each packer and the particular specifications at the time of procurement.

U.S. infantrymen are seen here advancing through the streets of a German town in 1945. Note that the BAR man has a Supper unit tied to the back of his combat suspenders.

It was left to each packer as to how to close the outer carton. While the inner carton has two overlapping end flaps that were glued together prior to impregnation with molten wax, the closure of the outer carton could be either seal-flaps, like the inner carton, or tuck-in flaps. This is not a specific early or late feature, but depended on the packager's capability and whether or not it had machines for glueing the flaps shut. If not, the cartons had to be hand-closed, using the tuck-end style.

A GI is putting a Breakfast and a Supper unit in his shovel carrier before going into an assault in Germany, 1945.

Over time the carton grew slightly larger. Originally the outer carton was a snug fit over the inner carton. The height of the inner carton was dictated by the height of the 300 x 106 tin can. When the tin can was inserted into its protective sleeve, the height of the inner carton, and subsequently the outer carton, had to be increased.

As of September 1945, specifications for the outside dimensions of the outer carton were 3 20/32" wide, 1 20/32" high and 6 30/32" long.

Conclusion

Okay, so I came up with four different main types; these are the distinctive changes in the outer cartons:

Type I: Only the nomenclature "U.S. Army Field Ration K" with type of unit is printed on the box. (late 1942 production)

Type II: Suggestions are added to the front panel of unit. Components are listed on the back. (February 1943)

Type IIIa: Nomenclature is changed to "Ration, Type K". (May/June 1943)

Type IIIb: Malaria warning is added on a side panel. (February 1944)

Type IVa: The colored "morale" boxes are introduced. Components are the same as Type IIIb, but are mentioned in a more generic list. (May 1944)

Type IVb: Due to inclusion of cereal and extra coffee, the components list is changed. (late 1944). Salt tablets were later added to the Dinner unit list in 1945.

Inner Carton

Early, experimental, K Rations consisted of three individual cardboard boxes in which the packages of the various foodstuffs were packed. These boxes were dipped in wax to seal against gas and to make the box waterproof.

When the K Ration went into full production, six types of waterproofing methods were specified in May 1942. Each prime contractor would waterproof the rations, using a synthetic wax, as stipulated in the contract. The method of waterproofing depended on the capabilities of the company. The type VI method, however, seems never to have been used.

Type I: The carton is coated inside and outside with wax. The printing will be on the box.

Type II: The carton will be dipped in molten wax, then overwrapped with waxed kraft paper and then dipped again in molten wax. The printing will be on the waxed paper.

Type III: The (inner) carton will be dipped in molten wax and then inserted into a snugly fitting (outer) carton. The printing will be on the outer carton.

This official photo is misleading in that it shows two different types of cartons.

On the right are two early Type II units in waxed (overwrapped) cartons. In the back are the Type III outer carton with opened inner carton (this is a tuck-in carton overwrapped and waxed), with the contents laid out on the left.

Type IV: The carton is of a telescoping type, wrapped with adhesive waxed kraft paper making complete contact with all surfaces of the carton. The carton then will be dipped in molten wax and overwrapped again with waxed kraft paper. The printing will be on the outer waxed paper.

Type V: All components are sealed inside a laminated cellophane bag. This bag is placed in a telescoping carton that is overwrapped twice with waxed kraft paper. The seams of the wrappings are opposite of each other. The printing will be on the outer wrapping.

All cartons have an inside dimension of 3 13/32" wide, by 1 13/32" high, and 6 19/32" long.

Type VI: The container consists of a square fiber-body box (with rounded corners) that is coated inside and out with wax and is closed with black metal ends. A printed kraft paper label will cover the body of the fiber-body box completely.

A Supper unit packed by The Hills Brothers Co., using a waxed paper wrapping that has been printed in a repetitive pattern. (photo: K Ration Info)

It was found that the waxed units would stick together when stored in warm climate. To prevent sticking, Type III was preferred, or if the inner carton was wrapped in waxed paper it was inserted in an outer carton. From now on a distinction was made between the inner carton and outer carton. Early productions appears to be Type IV. Later the Type III appears to be the preferred type.

This appears to be the first type of packaging (Type IV) used when the K ration was procured in greater numbers. This type was mainly used during training and field tests to test the new K Ration. (photo: 1944Supply)

Note how the tray fits inside a cardboard sleeve, then both are overwrapped with waxed paper. The whole package is then protected by the outer carton with tuck-in flaps. This method of packaging is what is referred to as the telescoping type. (photo: 1944Supply)

Above is a still from the film "Food for Fighters" (1943). The trays on the conveyor belt are being filled with the separate ration components; chewing gum is just being placed on top of the biscuits. Next, the can is placed towards the open end of the tray. Note that the equipment is crudely made from wood.

An alternative package found with early production is the inner carton being wrapped twice with waxed paper and then inserted into the outer carton. Since the first wrapping sticks completely to all surfaces of the inner carton, it appears that the inner carton might be waxed as well.

A Beech-Nut produced Breakfast unit inner carton that is only overwrapped twice with waxed paper, then inserted in an outer carton. The outer carton is dated 12-42. (photo: K Ration Info)

A close up of a Chicle produced Breakfast unit shows the double wrapping with waxed paper. The first wrapping is stuck firmly to the inner carton with the second wrapping folded loosely around it, with the seam opposite of the first layer. (photo: 1944Supply)

For identification purposes, the outer carton was printed, as prescribed earlier in the outer carton section, but it was left to the packer whether or not the inner carton needed to be marked for identification on the production line. Early on, some contractors didn't deem it necessary to mark the inner cartons, others simply used the same printing as used on the outer cartons.

Later in the war it became more common to mark the units with "BREAKFAST UNIT", "DINNER UNIT" or "SUPPER UNIT", or just "BREAKFAST", " DINNER" or "SUPPER".

"SUPPER UNIT", this is the most used type of printing on the inner cartons for identifying the units. The thick layer of wax, resulting from the double dipping, can be clearly seen on this example. (photo: 1944Supply)

Some contractors used the complete nomenclature on the inner carton. This Patten Food Products Breakfast unit has the nomenclature printed only on one main panel.

The wax used for dipping was a synthetic compound with a melting point higher than 140°F which would not crack or chip at -20°F. It could not be sticky at 120°F. The wax was odorless, tasteless and non-toxic.

The waxed inner cartons all have a brown appearance. This is not caused by the color of cardboard used, but is due to the brown hue of the wax itself. The color for the wax was set at a maximum 240 within the Red 500 Series of the Lovibond scale. (a color scale for liquids).

Usually, the dipping was done twice. The first dipping was done at approximately 190°F for 5 to 10 seconds to impregnate the cardboard. After a cooling period a second dipping was done with wax at a slightly lower temperature to coat the carton with a uniform protective overall coating.

A waxed carton should withstand immersion for 20 hours.

K Ration units are placed on the conveyor belt of a wax dipping machine at a prime contractor in New Richmond, Wisconsin (6-28-1944).

Note that all three types of units are being waxed. This is why the inner cartons are labeled, so that after dipping all units are placed in their corresponding outer cartons.

Occasionally the inner cartons were marked with an embossing or imprint showing the name of the unit or just the letter "B", "D" or "S".

A large, faintly imprinted "B" can be seen as the identifier for a Breakfast unit.

When the tin can was inserted into the cardboard sleeve, the inside dimensions of the inner carton was increased to 3 16/32" x 1 16/32" x 6 26/32" to allow sufficient room.

In specifications of 1945, five methods of waterproofing are described. These methods not only refer to the waterproofing of the inner cartons, but also to the final packing in the shipping case. After waterproofing, all inner cartons are placed in an outer carton.

Waterproofing Method I, II and III are all the same with the difference being in the final packing of the shipping cases. Method I, IV and V are packed in a fiberboard box. Method II and III are packed in a corrugated box that is placed inside a kraft paper laminate bag, both methods using a different style of bag (see the SHIPPING CASE section).

Method I, II and III: The inner carton will be dipped in molten wax, and after cooling down dipped again in slightly cooler molten wax for an overall coating.

Method IV: The inner carton is wrapped in a triple-ply laminated sheet made of one layer each of sulphite paper, aluminum foil and kraft paper. This laminated sheet is waxed on the outside and, when wrapped, the seams are heat sealed. A second wrapping of waxed kraft paper is applied with its main seam opposite the first wrapping.

A Method IV inner carton has been cut in half, showing clearly the aluminum foil laminate. The dark band is from the overlapping waxed paper overwrap. (photo: 1944Supply)

A Method IV laminated inner carton wrapping that has been printed with an "S" to indicate it is a Supper unit. The laminated wrapping was produced on a roll with a repeating "B", "D" or "S" printed along its entire length.

The picture above shows the kraft side and the aluminum foil side is shown below.

Method V: The inner carton is wrapped with the same laminated sheet as described in Method IV, but instead of a second wrapping the carton will be dipped in molten wax.

The first method (I, II and III) is prevalent.

Cellophane Bag

All food products, except the canned egg, cheese or meat product and the chewing gum, were sealed inside a cellophane bag for further protection against moisture. Originally the contents were packed loose in the box, but when the K Ration went into full production a cellophane bag of single thickness was used to enclose the biscuits, sugar, confection and beverage.

.png)

The cellophane bag contents from an early 1944 Breakfast unit.

With the early packages it was found that the cellophane bag would crack or tear where the confection (3 15/16" long) protruded. To prevent this all confections were to be not longer then 3 1/8 inch long.

On the right: an early Supper package with the longer D-bar protruding past the three sugat tablets. Left: a Breakfast package with a fruit bar of 3 1/8" length, making it a neat rectangular package. There is enough room for a row of four sugar tablets across the bottom of the cellophane bag.

Further development on the protective qualities of the K Ration packaging led to experimentation of different types of bags. Cellophane laminated to aluminum foil or kraft paper, or a lead foil laminated to paper were tried, but not deemed durable. A new bag made of a two-ply cellophane (cellophane laminated to cellophane) was standardized as the only acceptable type of packaging in 1943.

A bag from a 1942 K Ration packed by the Cracker Jack Company. It appears to be made of glassine laminated to cellophane. (photo: 1944Supply)

Candy-coated Beechies chewing gum is included inside the cellophane bag of this 1945 Dinner unit. (photo: 1944Supply)

The chewing gum was not to be included inside the bag because the flavor could be imparted to the other components. Only later in the war when candy-coated chewing gum became available again was it allowed to be included inside the cellophane bag. Usually, the K Rations produced in 1945 have the candy-coated chewing gum.

Contents

The complexity of the ration has been defended as follows: "While this ration has seemed unnecessarily complex to some, the variety contained in it is deliberate. No simple ration has yet been found which did not became tiresome within a few days that the test subjects did not eat sufficient to meet their nutritional requirements"

As already mentioned in the Outer Carton section, I have made a distinction between the different designs of the outer carton: the experimental K Ration and four different main types (with two sub-types).

In this chapter I will explain the various compositions of the unit contents, according to the types of outer carton design.

Where possible I have illustrated the different compositions.

Experimental K Ration

Although officially adopted and standardized in November 1941 as the U.S. Army Field Ration K, this version was only produced in small numbers for field tests. For its first field trial, only 6000 rations were produced.

Breakfast Unit:

- Defense Biscuits

- Graham Biscuits

- Can Veal Luncheon Meat

- Malted Milk Dextrose Tablets

- 2 Packages Soluble Coffee

- 3 Sugar Tablets

- Chewing Gum.

Dinner Unit:

- Defense Biscuits

- Graham Biscuits

- Can Pork Luncheon Meat

- Dextrose Tablets

- Tube Bouillon Paste

- Chewing Gum

Supper Unit:

- Defense Biscuits

- Graham Biscuits

- Can Cervelat Sausage

- D-Bar

- Lemon Juice Powder

- 3 Sugar Tablets

- Chewing Gum

Type I

In 1942 the new K Ration was procured on limited basis only for field trials, mass production went into high gear in the fall of 1942. Due to the many changes, the early production of the K Ration is printed only with the nomenclature and unit on the outer carton. The confections are of the long variety (3 15/16"). Cigarettes are included from the start.

Early Breakfast units contained a package of 15 Malted Milk-Dextrose and Dextrose tablets, and the Dinner unit contained a package of 15 flavored Dextrose tablets.

Due to the unpopularity of the Dextrose tablets, a Fruit Bar was substituted for the tablets in the Dinner unit. Soon after, the Malted Milk-Dextrose and Dextrose tablets are switched out in favor of the Fruit Bar.

The Supper unit contained three sugar tablets as well. They were not intended for sweetening the bouillon drink, though. The idea of including sugar was to sweeten the chocolate drink made with the D-bar.

A K Ration packaged in cardboard box and containing a fruit bar. Note that the three sugar tablets are not packed inside the cellophane bag, but the chewing gum is. (photo: 1944Supply)

The components of the Breakfast unit shown above after remove from the cellophane wrapper. (photo: 1944Supply)

Another Breakfast unit containing the Fruit Bar. Note the early protective cardboard for the can. The chewing gum was packed inside the cellophane bag. (photo: 1944Supply)

An early Type I Dinner unit that has the three sugar tablets packed separately from the other components in the cellophane. Note the protruding Malted Milk-Dextrose and Dextrose Tablets package. (The coffee is probably not original to this Dinner unit and should be an envelope of Lemon Juice powder.)

Type II

In February of 1943 the addition of instructions on the front panel of the outer carton was approved.

As of March 1943, all confections were shortened to 3 1/8".

The Malted Milk-Dextrose and Dextrose tablets were renamed Malted Milk-Dextrose and Dextrose Candy; 16 tablets fit in the new 3 1/8" packages.

Inclusion of a matchbook in one of the units was approved. The matches were already included on the production line before official specifications were drawn up resulting in the inclusion of the matchbook in the Supper unit sometimes instead of the Dinner unit. The Type II is only produced for three to four months.

The Supper unit still contains three sugar tablets. Later, shortly before the introduction of the toilet paper with Type IIIa, these were omitted.

A Supper unit packaged by the Hills Brothers Company, that includes a matchbook. (Not listed on the back of the outer carton.) The can is dated 3-43. Note that there are three sugar tablets as well. (photo: 1944Supply)

A closer look at the components from the Supper unit shown above. (photo: 1944Supply)

Type IIIa

The U.S. Army decided on standardization of all field rations in its inventory. The Mountain Ration, Jungle Ration and the 5-in-1 Ration were discontinued and superseded by the 10-in-1 Ration. From May/June 1943 all ration nomenclatures became the "Ration, Type …". This was also applied to the K Ration and the printing on the outer carton was changed accordingly.

In July 1943 a roll of toilet paper was added to the Supper unit. Soon after, the number of sugar tablets in the Breakfast and Dinner units were increased from three to four tablets.

The unpopular Malted Milk-Dextrose and Dextrose Candy were replaced by hard candies. Production facilities of the hard candies weren't considered adequate, however, and an alternative was found in new caramel candies (Choclettos) in the summer of 1943.

In the fall of 1943, the D-Bar was replaced with a Sweet Chocolate bar.

Orange juice powder is sometimes included as an alternative to the lemonade powder. The sugar in the Dinner units could either be four individually wrapped tablets, or a package of equal amount (23 grams) of granulated sugar.

A late Dinner unit showing progressive changes. The biscuits here are a package of the new type "C" square. This one came with Bouillon Powder.

Type IIIb

A warning against malaria was approved for the K Ration's outer carton in February 1944. This warning was later also printed on the matchbook cover, although the blank matchbooks are also still used.

The contents basically remain the same as with the Type IIIa.

Although the change to camouflaged coated cans was approved in late 1943, clear lacquered cans are still used due to existing stock.

Type IVa

A radical change in the packaging of the K ration was the use of different colors and design for easy identification of the units. The new designs went into production May 1944.

The composition of the contents of the K ration didn't changed much and is basicaly the same as the Type III ration.

The Breakfast unit contained the two packages, each with a different type of small biscuits. Coffee with four sugar tablets, the fruit bar, chewing gum and cigarettes. A can containing an egg product, here Ham and Eggs, is of the new camouflage coated production.

The new Dinner unit is basically the same as the Type IIIa shown above. This particular unit still uses the four individually wrapped sugar tablets instead of the new 23 grams package and the orange juice powder is sealed in a clear cellophane envelope.

The matchbook cover carries the warning against malaria and the can is also camouflage coated.

As an alternative to the Choclettos, York Milk Caramels are also used.

The biscuits used in the Supper unit are now predominantly of the square type.

The bouillon is still packaged in a clear cellophane envelope. The confection is the Sweet Chocolate bar. The Beef and Pork Loaf is also packed in a camouflaged can.

A Supper unit with the older notched style sleeve for the can, but the bouillon is packaged in an aluminum laminate envelope.

A Type IVa Supper unit with a cellophane bouillon envelope. (photo: 1944Supply)

Type IVb

In the fall of 1944, new specifications were issued on 31 October which changed the composition. This is a radical change from the composition of the previous types. In all units a wooden spoon is now included.

A compressed cereal bar was developed and replaced a package of biscuits in the Breakfast unit. Due to the smaller size of this cereal bar, the roll of toilet paper is now included in the breakfast unit. The back panel now includes instructions how to prepare the cereals. An extra envelope of soluble coffee product is added. The number of sugar tablets, however, is not increased.

The caramels in the Dinner unit are replaced with a candy bar, usually a Milky Way bar, or a kind of chocolate fudge bar. The 23 grams sugar package is replaced with a 1.2 oz. compressed block of granulated sugar. As an alternative to the lemon and orange juice powders, grape juice powder might be used.

To supplement the bouillon drink in the Supper unit an envelope of soluble coffee product is included. To sweeten the coffee, a package of 23 grams of granulated sugar is included, taking the place of the roll of toilet paper. The 2-ounce Sweet Chocolate bar is replaced with a package of caramels, either chocolate or vanilla flavor. Back panel now lists both coffee and bouillon.

In the summer of 1945, a small vial holding four salt tablets is included in the Dinner unit. The list on the outer carton now includes the text "salt tablets". The confection of the Supper unit is now either one of the two flavors of caramels, or two 1-ounce chocolate bars. In the fall of 1945 the matches were moved from the Dinner unit to the Supper unit.

The Type IVb being the final version and produced until 1946, this is the most often found intact version today.

An early 1945 Patten Foods Product Breakfast unit packed in a Type IVa outer carton.

Contents from a Type IVb breakfast unit. There were two different coffee brands included, both packaged by Henry Heide Inc. (photo: 1944Supply)

A 1945 Breakfast unit. Note the Chiclets chewing gum, and the sugar tablets made by the Manhattan Coffee & Sugar Co. The Lucky Strike cigarettes are noteworthy as well. (photo: 1944Supply)

Although the box still listed 4 lumps of sugar, there is a box of granulated sugar in this Type IVb Patten Food Products Dinner unit. It also contained a salt bottle.

This Type IVb Dinner unit still contains a blank matchbook and a notched sleeve. The inner carton is protected by a kraft paper/aluminum laminate wrapping. Note the small box that holds two candy-coated chewing gum tablets. (photo: 1944Supply)

Contents from a mid 1945 Type IVb Dinner unit with a chocolate fudge bar instead of the usual Milky Way or Mars candy bar. (photo: 1944Supply)

Contents of a late Supper unit showing two 1-ounce sweet chocolate bars as confection. Included within this particular Supper unit is a vial with salt tablets. (photo: 1944Supply)

Below shows an assortment of chocolate bars and cigarettes.